The Future of Mechanical Engineering: How the Discipline Is Evolving in a Smart, Automated World

- Kenneth Witz

- Jan 2

- 4 min read

Updated: Jan 2

Mechanical engineering has always been the backbone of modern industry. From steam engines to aerospace systems, the discipline has continuously adapted to the needs of society and technology. But today, mechanical engineering is undergoing one of the most significant transformations in its history.

Driven by automation, digitalization, sustainability demands, and advanced manufacturing technologies, the role of the mechanical engineer is no longer confined to traditional design and analysis. Instead, today’s engineers operate at the intersection of mechanics, data, software, and systems thinking.

This article explores how mechanical engineering is evolving, the technologies reshaping the field, and what this means for engineers building careers in an increasingly intelligent and automated

world.

Mechanical Engineering: A Discipline Built on Adaptation

Mechanical engineering has survived and thrived for centuries because of its adaptability. Historically, mechanical engineers focused on:

Designing mechanical components and machines

Applying thermodynamics, fluid mechanics, and materials science

Improving efficiency, reliability, and safety of physical systems

These fundamentals still matter, but the context has changed.

Modern products and systems are now complex, interconnected, and intelligent. A mechanical system is rarely “just mechanical” anymore. It interacts with electronics, software, sensors, networks, and data streams.

As a result, mechanical engineers are expected to think beyond isolated components and consider entire systems and life cycles.

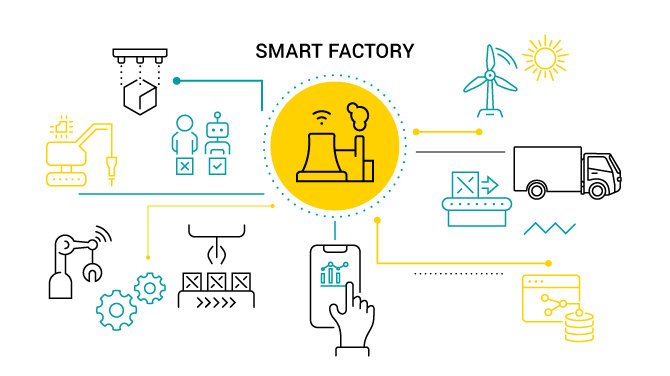

The Rise of Smart Manufacturing and Industry 4.0

One of the most profound changes in mechanical engineering is the rise of smart manufacturing, often referred to as Industry 4.0.

Smart factories integrate:

Sensors and real-time data collection

Advanced robotics and automation

Machine connectivity and digital twins

Predictive maintenance and analytics

Mechanical engineers now play a critical role in designing systems that generate, interpret, and act on data.

Instead of asking:

“Will this machine work?”

Engineers increasingly ask:

“How will this system perform over time, communicate issues, and optimize itself?”

This shift has transformed job roles. Mechanical engineers are now involved in:

Automation system design

Equipment data modeling

Reliability engineering using real-time inputs

Manufacturing optimization using analytics

Those who understand both physical systems and digital tools are in especially high demand.

Automation and Robotics: Redefining the Engineer’s Role

Automation is not replacing mechanical engineers, it’s elevating them.

Robots still require:

Mechanical design and structural analysis

Precision motion systems

Gear trains, actuators, and bearings

Thermal and fatigue considerations

What’s changed is the level of integration.

Mechanical engineers now collaborate closely with:

Controls engineers

Software developers

Electrical engineers

Data and automation specialists

This cross-functional environment rewards engineers who understand how mechanical decisions impact control logic, safety systems, and production efficiency.

Engineers who can design robot-ready systems, maintain tolerances under dynamic loads, and anticipate real-world wear are indispensable.

Advanced Materials and Lightweight Design

Materials innovation is another area transforming mechanical engineering.

Modern engineers work with:

Advanced composites

High-performance alloys

Lightweight structural materials

Engineered polymers and hybrid materials

The goal is no longer just strength, it’s strength-to-weight ratio, sustainability, manufacturability, and cost efficiency.

Lightweighting has become critical in industries such as:

Aerospace

Automotive and EVs

Renewable energy

Industrial automation

Mechanical engineers are expected to evaluate trade-offs between:

Performance

Manufacturability

Lifecycle costs

Environmental impact

This requires both analytical rigor and practical engineering judgment.

Additive Manufacturing: From Prototyping to Production

Additive manufacturing (3D printing) has matured beyond rapid prototyping. Today, it’s used for functional production parts, tooling, and complex assemblies that were once impossible to manufacture.

Mechanical engineers must now design for additive, not just for machining or casting.

This includes:

Optimizing geometries for internal lattices

Reducing part count through consolidation

Understanding anisotropic material behavior

Managing tolerances and post-processing

Engineers who understand both traditional manufacturing and additive processes gain a powerful advantage. They can select the right process for the right application, rather than forcing a single solution.

Sustainability and Energy Efficiency

Sustainability is no longer optional—it’s a core engineering requirement.

Mechanical engineers are increasingly tasked with:

Reducing energy consumption

Improving system efficiency

Designing for reuse and recyclability

Supporting renewable and clean-energy systems

From HVAC optimization to wind turbine design, mechanical engineering plays a central role in reducing environmental impact while maintaining performance and reliability.

This shift has expanded career opportunities in:

Renewable energy

Sustainable manufacturing

Energy systems engineering

Environmental compliance and optimization

Engineers who understand sustainability metrics and lifecycle analysis are becoming strategic assets, not just technical contributors.

The Changing Skill Set of the Mechanical Engineer

The most successful mechanical engineers today combine deep fundamentals with broad adaptability.

In addition to core engineering principles, employers increasingly value:

Systems thinking

Data literacy and analysis

Project and stakeholder management

Technical skills still matter, but so does the ability to:

Explain complex ideas clearly

Work across teams

Adapt to new tools and processes

Think strategically about long-term system behavior

Mechanical engineering is no longer just about solving equations, it’s about solving real-world problems at scale.

What This Means for Engineering Careers

For engineers navigating today’s job market, the opportunities are vast—but so are the expectations.

Companies are looking for engineers who:

Understand modern manufacturing environments

Can operate in automated, data-rich settings

Bring both technical depth and adaptability

Think long-term, not just task-to-task

This has also changed how engineers should approach their careers. Strategic moves, continuous learning, and alignment with the right organizations matter more than ever.

Final Thoughts: Mechanical Engineering Is More Relevant Than Ever

Mechanical engineering is not fading, it’s evolving.

As systems become smarter, more connected, and more complex, the need for engineers who understand how the physical world actually works has never been greater.

The future belongs to mechanical engineers who:

Embrace technology without losing fundamentals

Adapt to interdisciplinary collaboration

Think in systems, not silos

Continuously refine their skills and perspective

In an automated world, mechanical engineers remain the architects of motion, energy, and reliability, shaping the infrastructure that powers modern life.

.png)

Comments